In an era of rapid technological evolution, every aspect of our daily lives has transformed in recent decades. Phone booths and landlines gave way to smartphones. Clunky box TVs evolved...

Littoral operations carry a unique set of complexities including shallow waters, strong currents, and limited visibility. For covert coastal surveillance and rapid deterrence, DRASS manned and unmanned submersibles, DS8 and...

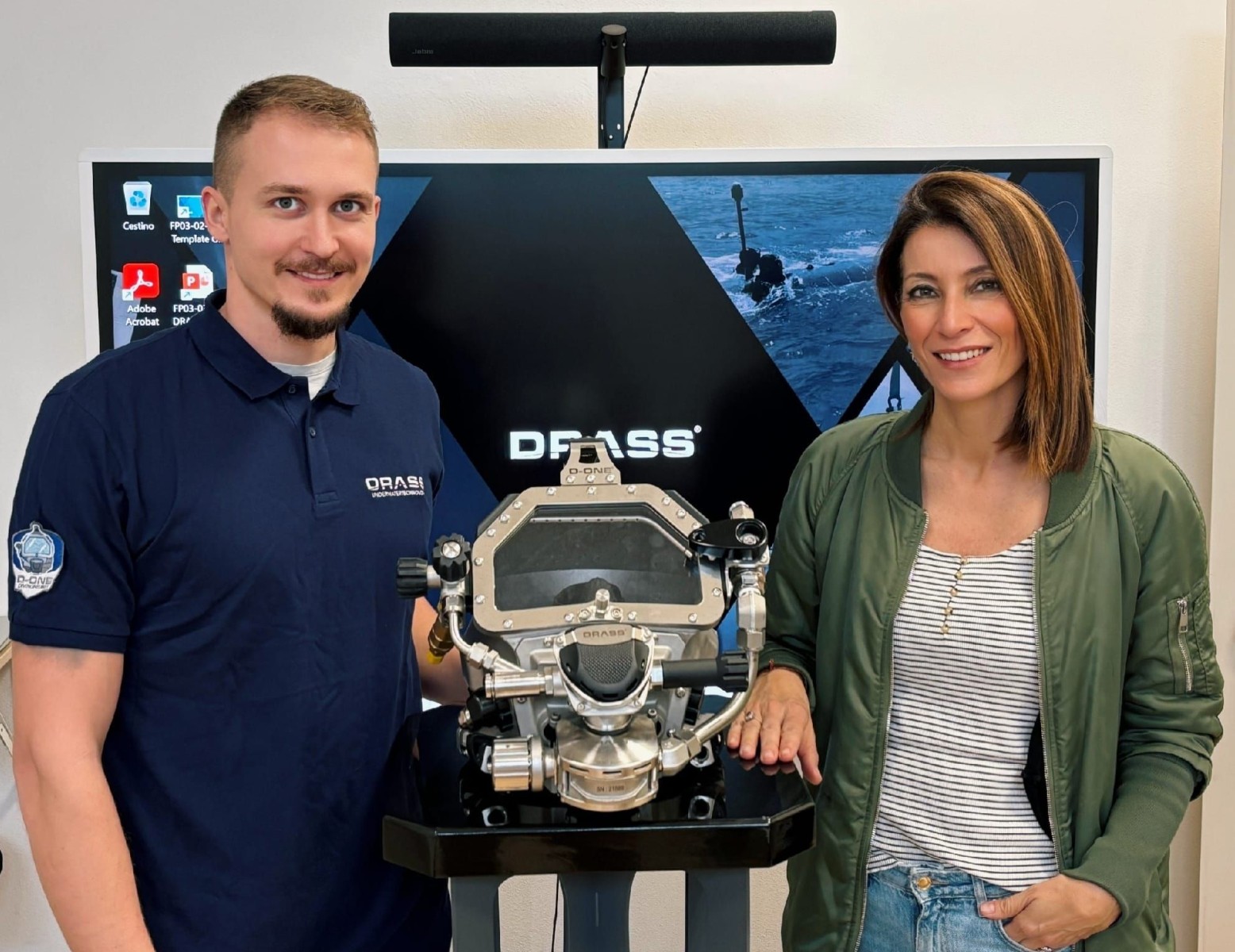

We’re thrilled to announce our new partnership with Deep Ocean Solutions for D-ONE helmet distribution in Sweden and the Nordic countries! We recently had the pleasure of hosting the Deep...

Last week, Drass Romania had the pleasure of hosting a distinguished delegation from the Italian Navy’s Submarine Rescue and Military Diving divisions. Fregate Captains Giovanni Torraco, Giorgio Gabriele Bisaglia, and...

After the incredible success of the D-ONE helmet at last week's Taucher-Tage exhibition in Regensburg, we are beyond excited to announce our partnership with Jan Siemon as our official D-ONE...

We were honored to welcome Captain Andrea Molaschi, from the Submarines and Underwater Dimension Department of the Marina Militare Navy General Staff, accompanied by Lieutenant Commander Roberto Bruzzesi, for an...

DRASS’ PLARS (Portable Launch and Recovery System), essential for launching and recovering Drass SRV (Submarine Rescue Vehicle), enables safe, efficient operations during high-stakes DISSUB rescue missions. Mounted at the vessel’s...

DRASS' manned and unmanned submersibles are rapidly emerging as key players in the underwater defence market, with deliveries underway and interest ramping up from clients approaching final negotiations. This success...

Last week, the latest class of Italian Navy submariners attending the Livorno Naval Academy's specialization course was hosted by Drass. Guided by Drass engineers and former submariners, the delegation toured...

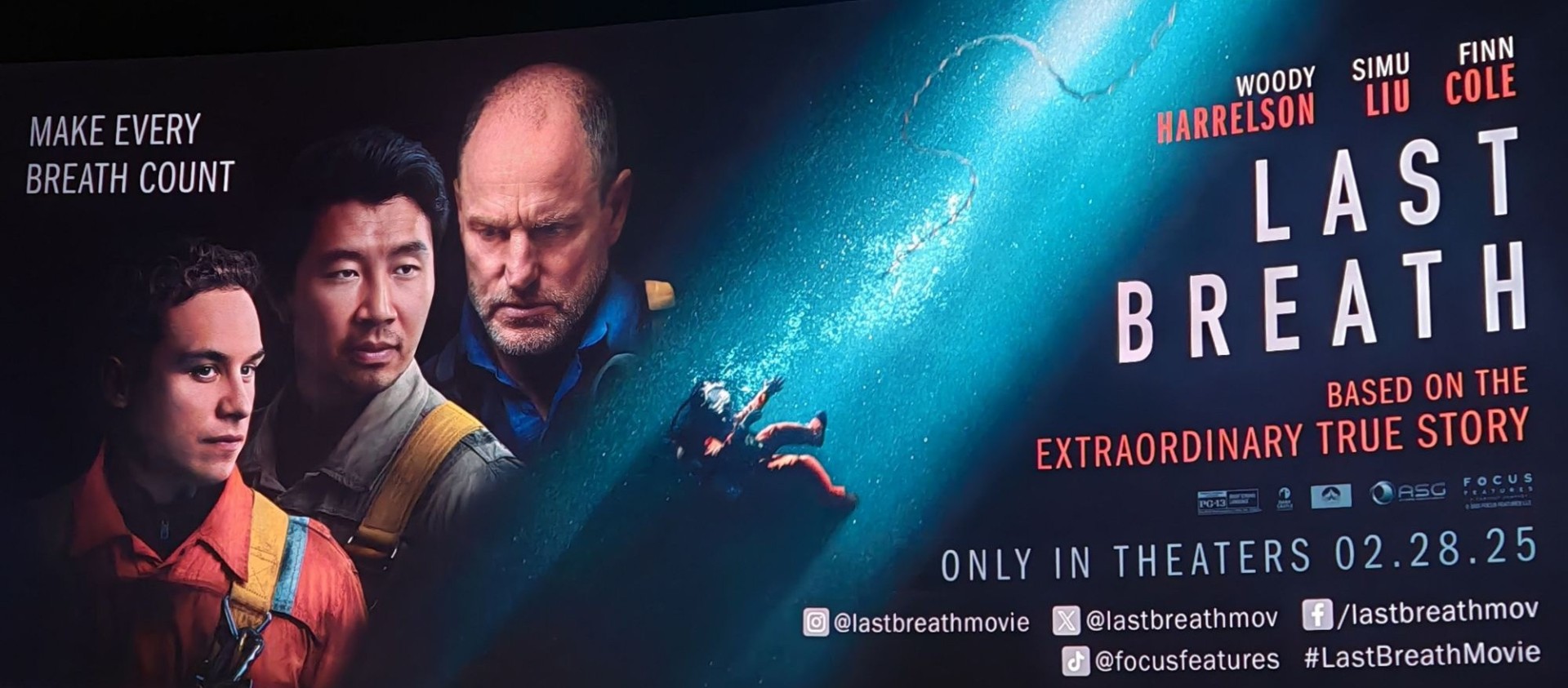

With Focus Features' highly anticipated subsea thriller Last Breath (2025) set for nationwide release in the US and UK on February 28, we are thrilled to present the first in...