Interchangeable with D-ONE AIR Pod, D-ONE PLUS Pod is specifically designed to protect divers in dirty water and is certified according to EN 15333-1. When the PLUS Pod is installed...

As part of DRASS' contract with the Italian Navy for a next-generation Submarine Rescue System, DRASS has been delivering specialized training to COMSUBIN, the Navy's SMER (Submarine Rescue & Escape)...

Thanks to the exceptional teamwork, professionalism, and expertise at DRASS, we continue to lead in cutting-edge technology in commercial diving, defence, and subsea rescue worldwide. 📉✍🏼🤿 The collaboration of our in-house...

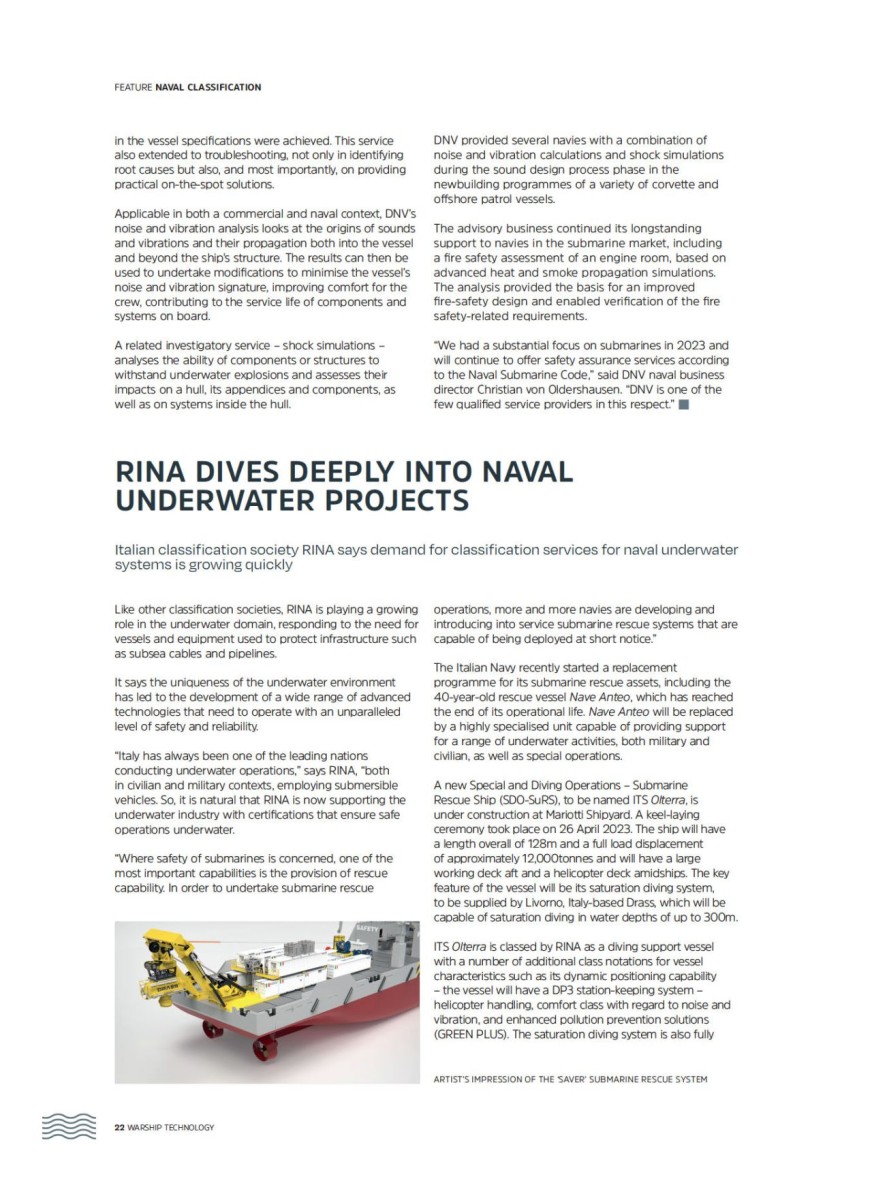

The Royal Institution of Naval Architects Warship Technology Journal 2024 Q1 Available now for public view, discusses the rising demand for underwater naval systems, for the protection of submariners and...

DRASS is committed to continually advancing technology in the underwater domain, addressing future challenges and evolving client requirements effectively. To this end, DRASS has been the first to understand the...

On June 13th, DRASS was delighted to host a delegation from the Polish Navy - Rear Admiral Włodzimierz KUŁAGIN, Head of Armament Division, and Captain (N) Cezary GNOZA, Head of...

On June 11th, DRASS had the pleasure of welcoming a delegation from Dongil Shipyard led by President Sung Tae KIM. The visit presented the opportunity for the signing of two...

On June 7th, DRASS had the pleasure of welcoming Walid Fouany, Plant Manager at CCC Consolidated Contractors Company (Underwater Engineering) S.A.L. This visit followed CCC's acquisition of the Diving Support...

Drass is thrilled to announce its participation in the upcoming Hollywood movie Last Breath that extensively features D-ONE commercial diving helmet, designed by Drass, throughout. Selected during filming rehearsals for...

On 23 May Drass welcomed a delegation from the Secretariat General of Defence and National Armaments Directorate led by Lt. Gen. Luciano Portolano. During the day’s program, the delegation toured...