Lars system

The mechanical setup to maneuver the diving bell and the clump weight.

BELL HANDLING SYSTEM

The handling system is a hydraulically activated mechanical setup designed to independently maneuver the diving bell and the clump weight. Both components are fully controlled by the handling control system, comprising a console and PLC panel, which oversees the synchronized operation of the system and manages the power pack. This provides hydraulic power to the diving bell’s respective winches and trolley.

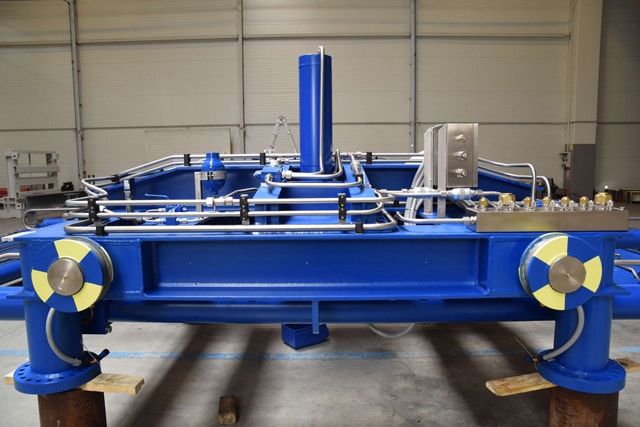

Trolley system

The trolley system allows the bell to be moved from the clamped position close to the hyperbaric chamber to the moon pool and vice versa. The trolley is equipped with pliers to release the bell for launching and catch the bell pins during the recovery operation.

The main features are:

Secure trolling thanks to a couple of hydraulic cylinders. The cylinders can fix the trolley in position, avoiding any movement of the bell due to vessel acceleration. Horizontal movement of the trolley from moonpool to mating position and vice versa.

Vertical movement is also available to align the diving bell man hole to the bell mate trunk.

Four legs are foreseen on the edges of the trolley in order to guide the bell smoothly the cursor inside the moonpool rails

Bell Handling Console

The Bell Handling Console is the control hub for the updated Drass iLARS system. Built in stainless steel, it features a Siemens 15” IP65 touch screen for interfacing with fail-safe PLCs and remote I/Os, plus a second screen for CCTV. Commands are issued via a redundant, SIL-certified joystick, and the console links directly to the LARS Control Panel, the core of system automation..

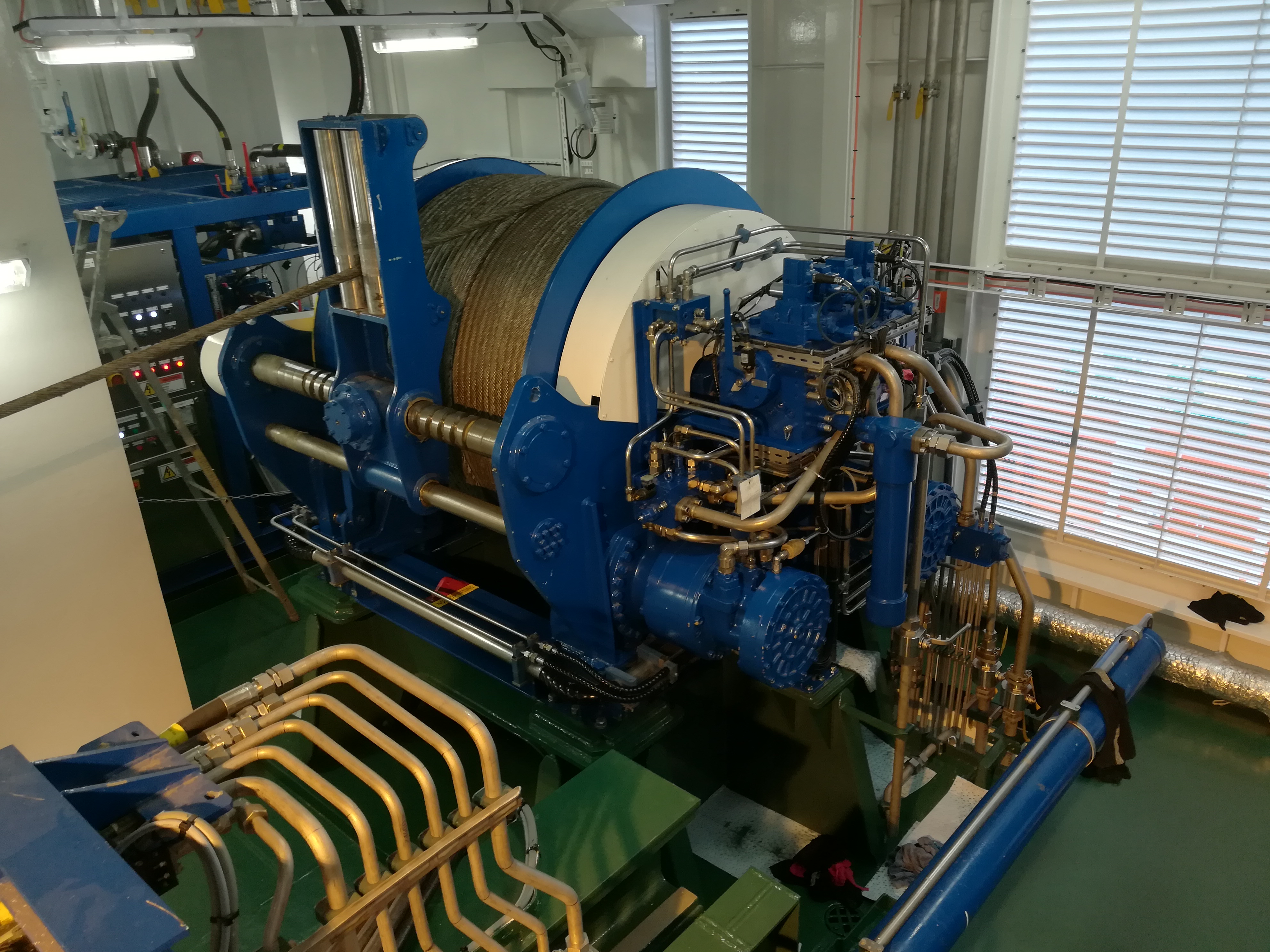

The Bell Winch

The Bell Winch operates the lowering and lifting of the Diving Bell up to the maximum depth. It is outfitted with a wire rope of 400 meters length and 36mm diameter (non rotating type). It is a single drum winch, hydraulic driven by means of two (2) hydraulic motors

passive heave compensator

The Passive Heave Compensator is installed to maintain the diving bell at its designated diving depth, within a specific range, irrespective of the vertical movement of the support vessel due to wave action. The heave compensator is automatically maintained in a central position with a simple pneumatic arrangement.

Umbilical winch

The umbilical winch is the essential link between the diving bell and surface systems, supplying vital services with constant tension. Powered by dual hydraulic packs, it uses a single drum with chain drive, pinion motor, and disk brake for precise control. The umbilical is spooled via a diamond-cut lead screw, and the winch stays in sync with bell lift operations during deployment and recovery.

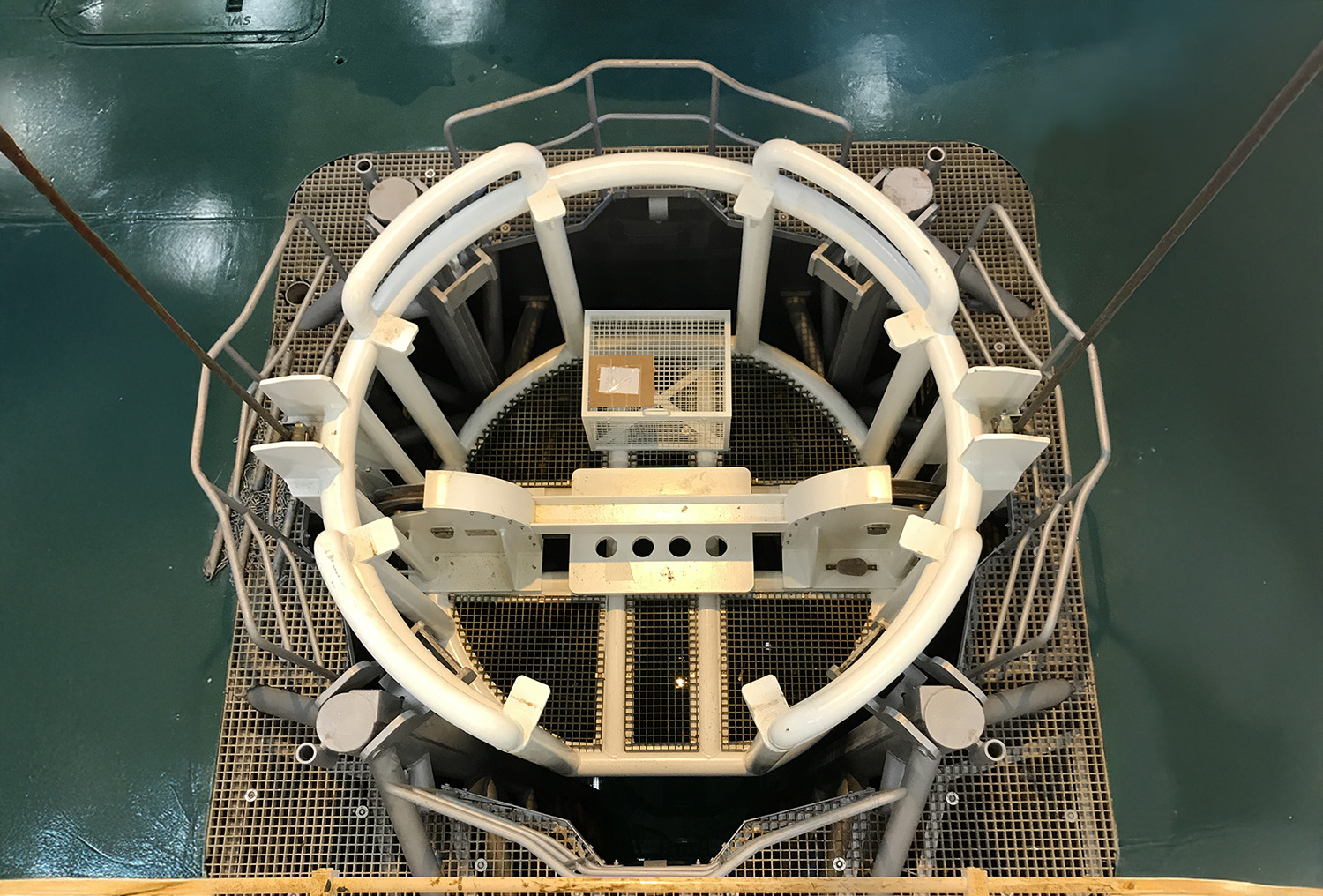

Bell cursor

The Diving Bell cursor drives the Bell through the moon pool. Each Cursor consist of a tubular frame which latches to, and encloses the upper part of the bell external frame and guides the same rollers along the vertical guides of the moon-pool.

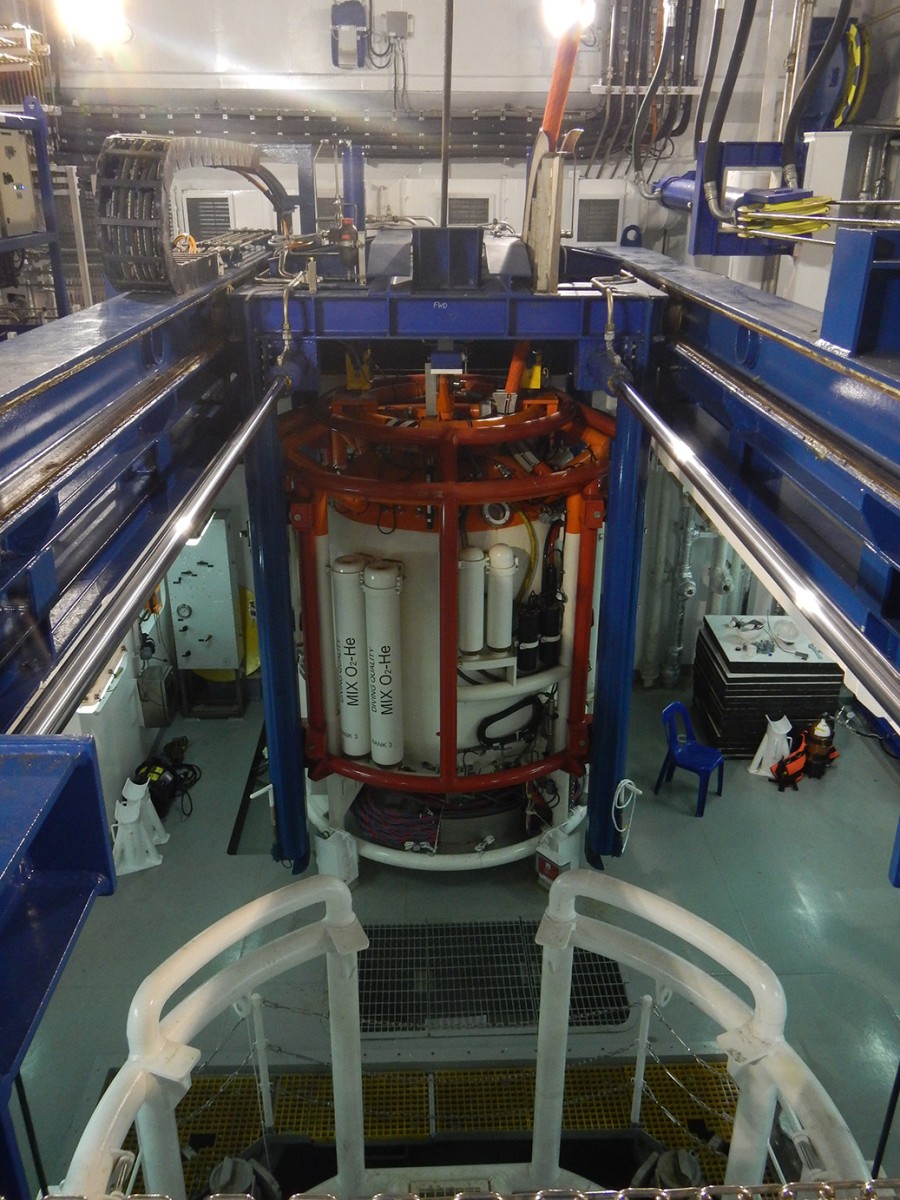

Drass Clump Weight

The Drass Clump Weight, an essential part of the handling system for the diving bell, safely leads the bell to working depth, stabilizing its descent / ascent, thereby ensuring the safety of the divers. It ensures alignment of the diving bell and the bell cursor during entry/exit of the moon pool and can allow emergency recovery of the diving bell.