SUBMARINE VENTILATION SYSTEM

Innovative submarine ventilation solution Drass design

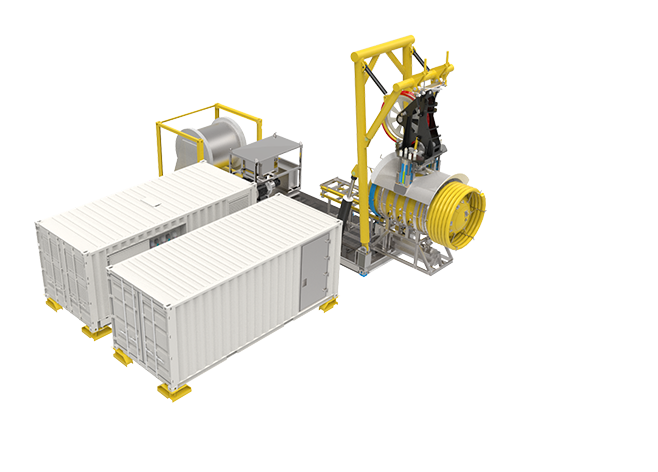

Drass Submarine Ventilation System

Designed to provide ventilation to a DISSUB even in the most challenging and distressed emergency situations.

The concept of DRASS is based on the utilization of an underwater Ventilation Capsule, containing a suction compressor which is therefore positioned immediately adjacent to the DISSUB. Thanks to the minimal size and length of the suction line, the compressor can satisfy the requirement of air recirculation without any pressure build-up inside the DISSUB, thereby operating at atmospheric pressure. By maintaining the atmospheric pressure in the Submarine, the evacuation of the DISSUB is achieved with a simpler, safer and faster procedure at every depth.

| Max. working depth | 600 msw |

| Air flow rate per person (as per NATO Std) | 30 Nl/m |

| Regulation of DISSUB internal pressure | Up to 50 MSW |

| Std DISSUB crew composition | Up to 60 pax |

| Max. continuous flow (per compressor module) | 200 Nm3/h |

Traditional ventilation systems, operate at depths of up to 650msw but require a progressive increase in pressurization from a surface pump. The pressurization process requires complex and long decompression procedures and imposes transfer under pressure to a hyperbaric chamber after the evacuation from the submarine. Excess of pressure in the submarine can also cause saturation issues in the crew, with serious consequences during rescue and transfer operations.

Keeping the DISSUB at lower pressure values, provides an insufficient flow of air to the DISSUB. While this is not perceived in a standard submarine ventilation exercise, in real operations the provision of insufficient flow of air can have fatal consequences for the DISSUB personnel due to the degradation of O2 content and the quick build-up of CO2.

The performance of Drass VS instead is independent of the depth of the DISSUB thereby ensuring that performance quality is not restricted by time and depth variables.

Drass can supply High Pressure air through a small hose (1/2”) included in the Strength Resistant Umbilical Cable, from surface to the Ventilation Capsule, where the air is reduced to Low Pressure. From the Ventilation Capsule, a sho rt hose having adequate diameter is connected to the DISSUB; the diameter of LP hose depends on the volume and crew of the connected DISSUB. A smaller diameter hose allows a significantly smaller umbilical winch, resulting in a SVS which can be easily air-deployable (ISO 20” container footprint).

The suction compressor directly vents the DISSUB exhaust air into water at depth, therefore Drass SVS does not require a large diameter suction hose to be connected to a surface vacuum unit from depth. The overall dimensions of the surface equipment and winches are thereby reduced.

The Ventilation Capsule is only a few meters away from the DISSUB. This makes it easier for the divers or for the Working ROV (Remotely Operated Vehicle) to connect the LP Supply and Suction Hoses even in conditions of strong currents. The short hose offers a considerably smaller resistance to the current compared to the hundreds of meters of hose tendered from an assisting vessel operating a conventional ventilation system.

Prolonged exposure to low temperature is one of the highest threats to the survival of a DISSUB crew. Thanks to the availability of local energy, and to the temperature monitoring provided by the Sensor Bar installed in the DISSUB, Drass SVS controls the temperature of the DISSUB by achieving the desired Supply Air Temperature on the local Ventilation Capsule.

DRASS SVS Air Distribution system is designed to carry out flushing with a redundant source of breathable, clean air. The flexible architecture of the system allows two additional services:

On Surface: thanks to dedicated outlets, the Supply Air is also available for the pressurization of the Diver Decompression Chamber and of the Submarine Rescue Decompression Chambers

At Depth: thanks to dedicated outlets, the Supply Air is also available to vent the submarine ballast tanks and increase the buoyancy of the DISSUB, when the rescue team brings the DISSUB to surface.